Facilities

Mechanical Engineering students have access to a wide range of academic, laboratory, workshop, and technical resources that support hands-on learning and professional development.

The Mechanical Engineering program is supported by a combination of dedicated laboratories, shared campus facilities, and specialized learning spaces that enable students to apply theory through practical work. Alongside classroom learning, students engage in experiments, prototyping, fabrication, testing, and project development using well-equipped workshops and technical resources available on campus.

Department Infrastructure Development

A dedicated five-storey Mechanical Engineering building is currently under construction. This upcoming facility will include two specialized floors for advanced laboratories and research activities, a full-scale workshop on the ground floor, smart seminar halls, faculty offices, and modern classrooms designed to enhance teaching, learning, and innovation. Until the completion of this building, the program continues to utilize well-established on-campus spaces, including a large central workshop and fully functional laboratory facilities that support academic and project-based requirements.

Mechanical Engineering Workshop▾

The Mechanical Engineering Workshop serves as the foundation for hands-on learning and practical skill development. It comprises nine specialized sections, including carpentry, metal casting, machining, welding, sheet-metal work, fitting, fabrication, and basic manufacturing practice. Students use this space to learn fundamental engineering skills, carry out project fabrication, and develop prototypes for coursework, design projects, and final-year research.

Materials Science & Testing Laboratory▾

This laboratory introduces students to the behaviour and properties of engineering materials. Facilities include equipment for tensile, compression, hardness, impact, torsion, and microstructure analysis. Students learn how materials respond to different loads and environmental conditions, enabling informed decisions in design, manufacturing, and material selection.

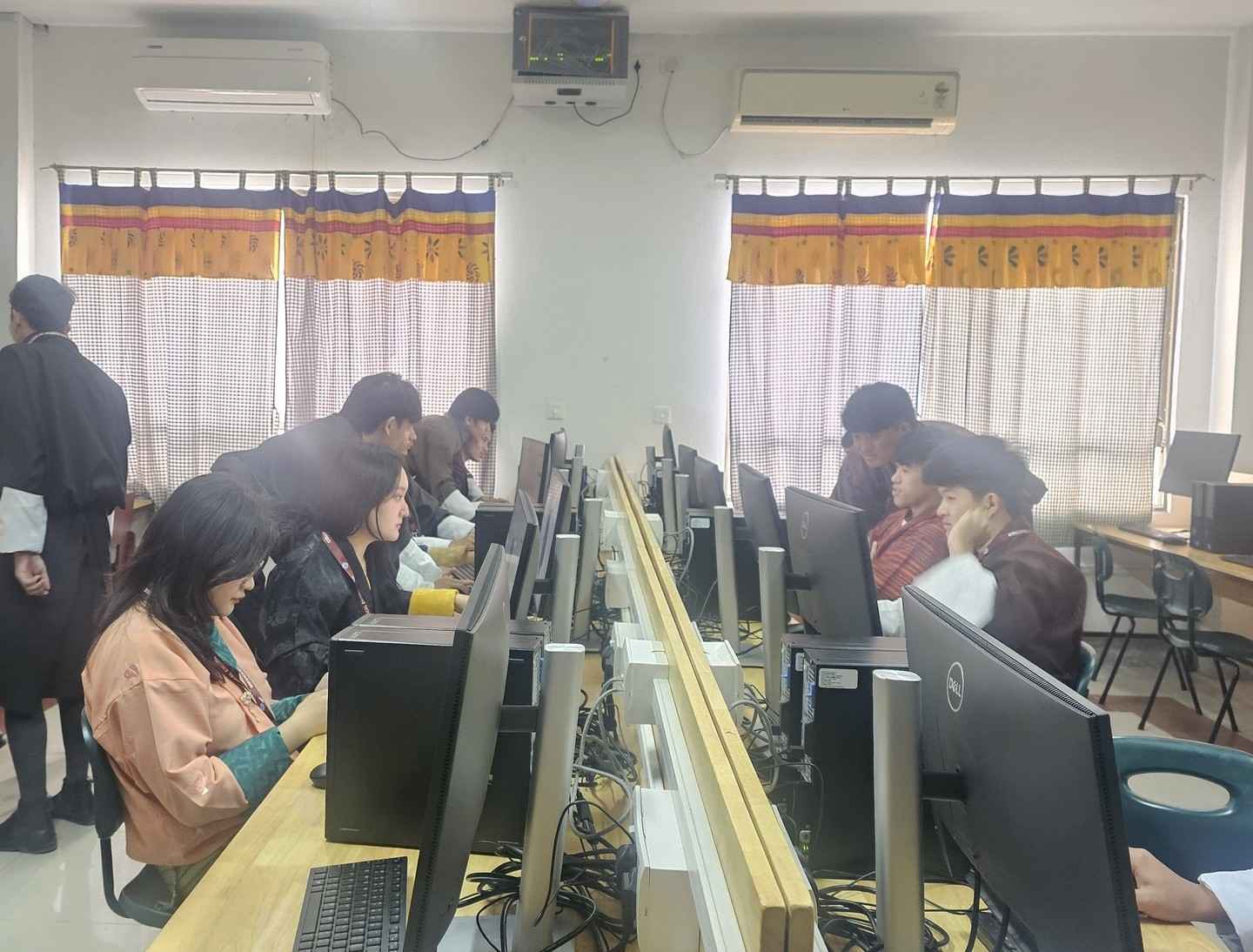

Computer-Integrated Manufacturing and Design Laboratory▾

The CIMD Lab supports computer-aided design, simulation, and analysis activities. Students work with software such as SolidWorks, AutoCAD, ANSYS, and CFD tools to perform 3D modelling, drafting, visualisation, and performance simulation. The lab is widely used for design projects, digital prototyping, and computational engineering tasks.

Metrology Laboratory▾

The Metrology Lab is equipped with precision measuring instruments such as vernier systems, micrometers, height gauges, slip gauges, profile projectors, and surface-finish testers. Students learn dimensional inspection, tolerance analysis, and quality-control techniques essential for manufacturing and industrial applications.

Advanced Manufacturing Laboratory▾

This modern laboratory supports high-precision fabrication and advanced industrial processes. Facilities include CNC laser welding, CNC laser cutting, CNC tube-sheet cutting, automated forming systems, and a CNC press brake machine. Students gain exposure to contemporary manufacturing technologies used in industry and apply them in design and fabrication projects.

Engineering Thermodynamics Laboratory▾

The Thermodynamics Lab introduces students to thermal systems and energy-conversion processes. Equipment includes engine test rigs, calorimeters, refrigeration trainers, and performance analysis units. Students evaluate thermodynamic cycles, fuel properties, and basic heat-to-work conversion mechanisms.

Kinematics & Dynamics of Machines Laboratory▾

This laboratory helps students understand motion, forces, and vibration behaviour in mechanical systems. Experiments include cam and follower mechanisms, gear trains, balancing of rotating masses, gyroscopes, and vibration analysis rigs. Students examine the dynamic performance of machines and analyse real-world mechanical motion.

Heat & Mass Transfer Laboratory▾

The Heat and Mass Transfer Lab provides hands-on experience with conduction, convection, radiation, heat exchangers, and diffusion processes. Students perform experiments to study thermal behaviour, evaluate efficiency, and understand how heat flows through various systems and materials.

Automotive Engineering Laboratory▾

This laboratory supports coursework related to vehicle systems, powertrains, EV components, fuel systems, and engine operation. Students explore modern automotive technologies, including electric-vehicle subsystems, vehicle diagnostics, braking systems, chassis components, and performance evaluation methods.

HVAC & Refrigeration Laboratory▾

The HVAC Lab provides practical exposure to heating, ventilation, air-conditioning, and refrigeration systems. Students carry out psychrometric analysis, refrigeration cycle experiments, AC system testing, and air-flow measurements. The lab also serves as a platform for ASHRAE-related student activities, workshops, and hands-on training in sustainable building systems.

Where Mechanical Engineering students transform ideas into reality—working hands-on with machines, tools, and equipment that build true engineering ability.